Reviewed by Anurag Mishra (Sr. Technical Consultant)

Invisible Weaknesses in Textile Products: In textile production, strength and strength can be a determining factor in making or breaking the image of a good brand. Imagine this: A customer buys a top quality sportswear, which after very few uses begins to tear. Failure at this level does not mean simply shipping the product back but rather losing brand loyalty and future sales. Then, what is the criterion by which a manufacturer comes to be sure that their luxurious silks, fragile by their very nature, or even the toughest cotton mixes, created for strength, will be able to withstand the strain and wear of everyday life?

This is where the Universal Tensile Testing Machine (UTM) comes in.

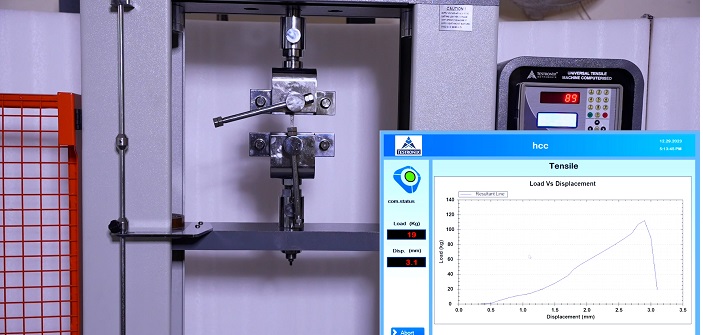

A Universal Tensile Testing Machine stretches a material to a breaking point by continuously stretching it. It is generally a very important test within textiles, used to test polyester, nylon, and cotton strengths.

This machine stretches the piece of fabric to a breakpoint and thus gives some useful data regarding how much stress the textile material could take before ripping it apart. The data will be presented in units of Newtons (N) or megapascals (MPa).

Testronix Instruments have more than 40 years of experience in quality control and testing solutions, and it has developed a reputation for providing extremely dependable Universal Tensile Testing Machines.

For leading textile groups, Testronix stands as the epitome of excellence and dedication to its work. Our machines are built with the latest technology to provide you with exact, reproducible results, thus saving you from costly mistakes such as product recalls and ensuring consumer satisfaction.

Clamping a piece of fabric between two grips on the machine will automatically get a fabric test through tugging from both ends.

At this point, the equipment records some very critical data including elongation at break (the point at which the fabric snaps) and tensile strength.

Result? Manufacturers can identify weak points and modify manufacturing processes to engineer stronger, better-quality products.

Tensile testing is a way of protecting against failed products. Poor quality textiles lead to dissatisfied consumers, product recall, and worst still, damaged reputations. A UTM helps avoid such problems by pointing out potential defects early in the development cycle. This allows the final product to be at par.

For example, take sportswear. Running fabrics must withstand repeated stretching and motion without deteriorating their integrity. A UTM ensures that spandex blend in leggings or compression wear would not fail its function after a few wear times.

This particular machine holds much significance for the textile industry and performs an important function in the process of testing and determining various materials' mechanical properties. These materials range from fibers and yarns to fabrics, all of which are significant when making the proper assessment of their characteristics and performance.

Tensile Testing is conducted to ascertain the tensile strength of various fibers. As a result of such tests, one is capable of indicating just how much force a material can take before it totally breaks. Noting this aspect of materials helps guarantee the long-term durability and dependability of fibers and fabrics used in clothing and other industrial applications where the utmost strength is anticipated.

UTMs measure the elongation or stretchability of textiles, which can be of utmost importance in sportswear fabrics or materials requiring flexibility.

UTMs are used specifically to test a variety of fabrics for tear and puncture resistance. This is one crucial testing since it ensures these materials attain the necessary strength standards that are very vital for protective clothing and other industrial applications demanding high levels of durability and resilience.

UTMs also test the seam strength of stitched fabrics to assess the strength and durability of stitched textile products during various applications such as fashion, upholstery, etc.

Quality Uniformity: UTMs ensure that each lot manufactured is of the same strength so that there would not be any formation of weak points.

Longer Product Life: Weak points in textiles improve product life by corrective measures during the manufacturing process.

Customer Confidence and Brand Image: A worthy product ensures lesser return, contented customers, and a good reputation.

Capacity: 5 kN to 50 kN. Suits for testing light to heavy fabrics.

Speed: 0.1 mm/min to 500 mm/min. This allows the device to test under a wide range of conditions.

Accuracy: Loads can be measured within +/ -2 % for very accurate outcomes.

User Interface: Digital display with advanced software for easy analysis.

Material: Let yourself know about the material type you are going to test. Is it a light silk or a heavy canvas? Make sure that the UTM you choose is capable of that.

Force Range: Ensure that the product can apply the amount of force you need without exceeding its load-carrying capabilities.

Software Integration: Assess their capacity to integrate its use with software for best ways to analyze and report the data.

A UTM can test a range of textiles: cotton, polyester, nylon, silk, and blended fibers such as spandex.

Tensile strength (MPa) = Force (N) / Cross-Sectional Area (mm²).

Each spool of fabric should be tensile tested to ensure uniformity in the quality of each spool of fabric.

Take the Next Step

Invest in a Universal Tensile Testing Machine from Testronix Instruments and ensure that your brand's products are failure-proof. Safeguard your good name, ensure reliable products, and deliver excellent quality textiles to your customers.

Contact us today to know more about how our UTM can fit right into your production line and make your product of superior quality.