.png)

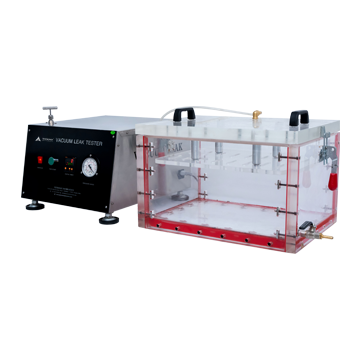

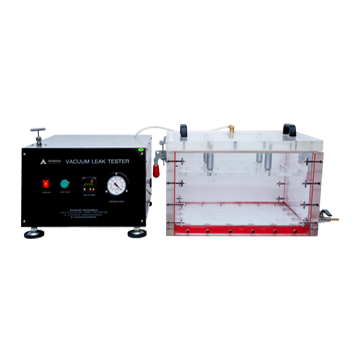

A Leak test apparatus is an instrument used to identify leaks in sealed packages. This apparatus is most commonly used in the pharmaceutical, packaging, and food industries to ensure product quality and safety in compliance with international standards. The leak test apparatus is used to check packaging using rules and guidelines or standards created by global groups like ISO and ASTM to make s...

A leak test apparatus is highly precise equipment that finds and measures leaks in sealed items, containers, or systems by using a controlled difference in pressure and keeping track of the results. The main purpose of the leak test device is to verify integrity, quality, safety, and conformance to standards, specifically in the food, pharmaceutical, and automotive industries.

This procedure is achieved by placing a vacuum in a closed chamber to test whether or not the package is in its shape and intact, signifying the presence of a remarkable, spill-free seal. If the packaging deforms or a second test is done after the vacuum is released, such as a dye penetration test, then it means the seal has failed.

The advantages of using a leak test apparatus include enhancing product quality, saving money, and increasing customer trust in the product, as it detects even small leaks in a non-destructive manner. The benefits of the use of the Testronix leak test apparatus are as follows:

Improved Product Quality

Leak test equipment ensures that all packages or units are sealed and defect-free. It eliminates contamination, spoilage, and failure of products by identifying the smallest leaks. This leads to quality consistency, increased shelf life, and better reliability on the part of the consumer and manufacturers.

Cost Savings

Early detection of leaks helps manufacturers to avoid product recalls, rejections, and wastage. Inspection of defective packaging prior to shipping avoids loss of money and lessens the cost incurred in the repair or replacement of damaged products. The quality control mechanism reduces operation costs and increases efficiency in production substantially over time.

Enhanced Customer Trust

The leak-free packaging gives confidence to the buyer about product safety, freshness, and reliability. With a robust leak test apparatus, businesses can easily measure even very minute leaks on their products whether it is corrugated boxes or bottles, before it actually delivered to the end customers. This trustworthiness builds customer loyalty, better brand recognition, and boosts sales repetition in competitive markets.

Improve Brand Reputation

A leak test equipment enables companies to produce quality and safe products with minimal complaints and failures. Customers who get quality products that are not defective perceive the brand as a trustworthy and professional one and this is what highly matters for the businesses.

Leak test apparatus finds various applications in industries to achieve product safety, quality, and integrity through leakage detection within seals and components in industries such as automotive, electronics, medical, and packaging. The primary applications of leak test equipment are as follows:

Automotive Industry

It has applications in the automotive sector, where leak test apparatus is used to test fuel systems, radiators, hoses, airbags, and engine components. Timely leakage reduces safety hazards and improves automotive performance and compliance with automotive standards, which helps manufacturers make high-performance, durable models.

Electronic leak test equipment ensures that electronic parts such as sensors, battery packs, and sealed circuits are dry, clean, and free of air. This avoids internal damage, short-circuiting, and failure of performance. Dependability in sealing is essential in very durable electronic products that are subjected to extreme or alternating environments.

Medical supplies such as syringes, IV bags, catheters, blister packets, and diagnostic equipment require flawless sealing. Leak test equipment ensures sterility and eliminates contamination. The process guarantees the safety of patients and the hygiene of products and helps to follow severe healthcare requirements and global standards of quality.

In packaging, leak tests are used to test bottles, pouches, cartons, trays, and vacuum-packed goods against defects in the seals. It provides an airtight seal for the packages, protecting the products from spoilage. This procedure keeps the manufacturers from producing the same quality products and adhering to the regulations to offer safe products.

A leak test apparatus is an instrument used to establish the leakage of products, packages, or components that are closed. It ensures that the product is airtight, safe, and meets the quality standards required in various industries such as food, pharmaceuticals, automotive, and electronics.

The apparatus for testing leaks is utilized by placing an item inside of it, applying pressure or vacuum to the item that has been sealed, and then observing any changes that may have occurred. It is possible for the machine to detect any air, liquid, or gas that escapes and affect the product in a later stage.

The industry standards like ASTM and ISO, have norms on a leak test apparatus, which they provide as guidelines to nondestructive testing methods. Additional standards are ASTM F2338-24 (non-destructive leak detection in packaging), ASTM D3078 (flexible packaging bubble test) and ISO 14457 (leak testing through vacuum decay)

A leak test apparatus price ranges from INR 25,000 to 350,000 in India and depends on accuracy and sensitivity, the level of automation, and the specific size and capacity. Other components such as digital displays, more complicated sensors, printers, or special fixtures may raise the cost. To make certain you are getting the best leak testing results, request a quote or contact us and accurately find the complex leaks!

Claim FREE copy of our latest Product Catalog.

Tell us where should we send your copy?

Tell Us What Product You are Interested In?